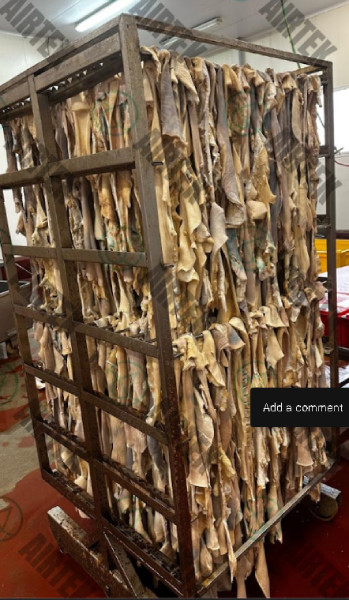

Modern food processing facilities face mounting pressure to maintain impeccable hygiene standards through advanced meat dryer technology. Contamination risks threaten both consumer health and business reputation. These sophisticated drying systems provide essential protection against foodborne pathogens that traditional methods often fail to address comprehensively.

A meat dryer represents cutting-edge technology designed to eliminate moisture-related contamination risks. These sophisticated systems create controlled environments that prevent bacterial growth through precise temperature and humidity management. Professional processors rely on this equipment to maintain consistent food safety protocols across their operations.

The Hidden Dangers of Improper Meat Processing

Traditional drying methods expose meat products to numerous contamination risks that can devastate entire production batches. Uncontrolled environments allow dangerous pathogens to flourish, creating serious health hazards for consumers and legal liabilities for processors.

Bacterial Growth Acceleration: High moisture levels create perfect breeding conditions for harmful bacteria including E. coli, Salmonella, and Listeria. These pathogens multiply rapidly in warm, humid environments typical of traditional processing facilities. Even minor temperature fluctuations can trigger exponential bacterial growth that renders entire batches unsafe for consumption.

Mould Formation Risks: Excess moisture promotes mould development that penetrates deep into meat fibres. Surface treatments cannot eliminate embedded contamination once mould establishes itself within the product. This contamination often remains invisible until advanced stages, making detection difficult and costly.

Cross-Contamination Exposure: Open-air drying systems allow airborne contaminants to settle on exposed meat surfaces. Dust particles, insects, and environmental pollutants introduce additional contamination vectors that compromise product integrity and safety standards throughout the processing cycle.

Controlled Environment Technology for Food Safety

Advanced drying systems create precisely controlled environments that eliminate contamination risks through scientific temperature and humidity management. These systems maintain optimal conditions that prevent pathogen growth effectively.

Temperature Precision Control: Modern equipment maintains exact temperature ranges that destroy harmful microorganisms without damaging meat quality. Consistent heat distribution ensures uniform processing across entire batches. This precision eliminates cold spots where bacteria might survive standard processing procedures.

Humidity Management Systems: Controlled moisture extraction prevents bacterial proliferation by maintaining optimal humidity levels throughout the drying process. Automated sensors continuously monitor environmental conditions and adjust parameters instantly. This responsive technology ensures consistent results regardless of external weather conditions or seasonal variations.

Air Filtration Protection: Advanced filtration systems remove airborne contaminants before they contact meat products. Multi-stage filtration captures particles, bacteria, and other harmful substances that could compromise product safety. Clean air circulation prevents external contamination through maintaining optimal drying conditions.

Advanced Technology Benefits for Hygiene Standards

Modern drying technology incorporates multiple safety features that traditional methods cannot match. These innovations provide comprehensive protection against contamination risks.

- Automated monitoring systems track temperature, humidity, and airflow continuously

- HACCP-compliant design ensures regulatory compliance and traceability

- Stainless steel construction prevents bacterial harbourage and simplifies cleaning

- Closed-system design eliminates external contamination exposure

- Real-time alerts notify operators of any deviation from safe parameters

Pathogen Elimination Efficiency: Scientific drying protocols destroy harmful microorganisms through controlled heat application and moisture reduction. This dual-action approach ensures complete pathogen elimination without chemical additives or preservatives. The process maintains meat quality through precise environmental control.

Consistent Safety Standards: Automated systems eliminate human error variables that compromise food safety in manual operations. Programmable controls maintain identical conditions for every batch processed. This consistency ensures reliable safety outcomes and regulatory compliance across all production runs.

Traceability Documentation: Digital monitoring systems create detailed processing records for regulatory compliance and quality assurance programmes. These comprehensive logs provide evidence of proper safety procedures during audits and inspections. Documentation capabilities support liability protection and brand reputation management.

Quality Preservation Through Scientific Processing

Advanced drying technology preserves meat quality through precise environmental control that traditional methods cannot achieve. Scientific processing maintains nutritional value and sensory characteristics effectively.

Nutrient Retention Optimisation: Controlled temperature profiles preserve essential proteins, vitamins, and minerals that high-heat processing often destroys. Gentle dehydration maintains nutritional integrity through gradual moisture removal. This approach produces superior products that meet consumer expectations for quality and nutrition.

Texture and Flavour Protection: Precise drying conditions maintain desired texture characteristics without over-processing or under-processing risks. Controlled environments preserve natural flavours through optimal processing parameters. Consistent results ensure customer satisfaction and repeat business opportunities.

Economic Advantages of Professional Equipment

Investment in professional drying equipment delivers significant cost savings through reduced waste, improved efficiency, and enhanced product quality. These economic benefits justify initial equipment costs through operational improvements.

Waste Reduction Benefits: Controlled processing eliminates batch failures caused by contamination or improper drying conditions. Consistent results reduce product losses and associated replacement costs. Reliable processing increases overall production efficiency and profitability margins.

Energy Efficiency Gains: Modern systems optimise energy consumption through advanced insulation and heat recovery technologies. Efficient operation reduces utility costs significantly compared to traditional methods. Smart controls prevent energy waste through automated system management.

Conclusion

Professional meat processing demands reliable contamination control that protects both consumers and business interests. Advanced drying technology provides comprehensive protection against bacterial growth, mould formation, and cross-contamination risks that threaten product safety. Investment in quality equipment delivers consistent results, regulatory compliance, and operational efficiency that traditional methods cannot match. Take action today to upgrade your processing capabilities and ensure your facility meets the highest food safety standards.